Contact

700 meters south of Donglitun Village, Xiliangwa Township, Anping County, Hengshui City, Hebei Province

Steel Springboard

- 产品描述

-

Product Introduction

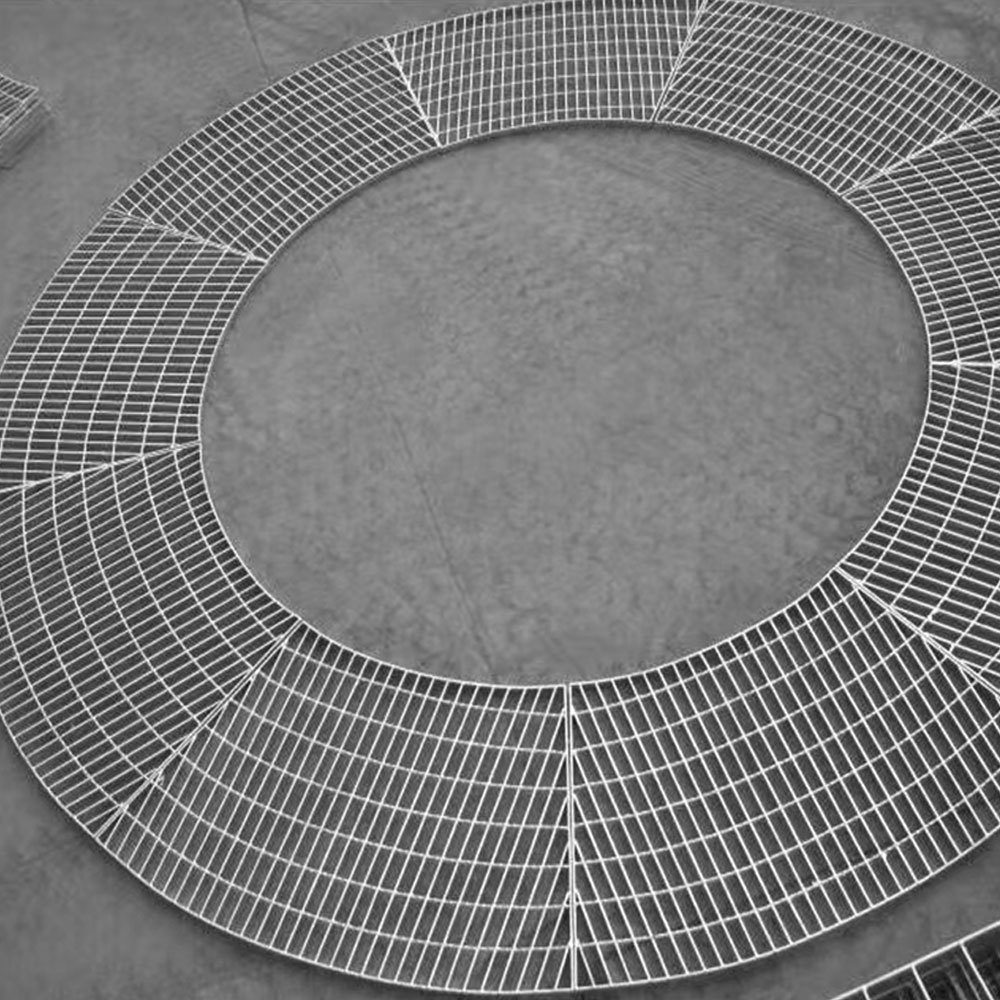

Steel springboard, as an indispensable tool in construction, is a key component for construction personnel to walk and stack materials when setting up scaffolding. It is made from steel as raw material and processed through a series of techniques. With excellent performance, it has been widely used in industries such as construction, shipbuilding, and petrochemicals.

Product Structure and Materials

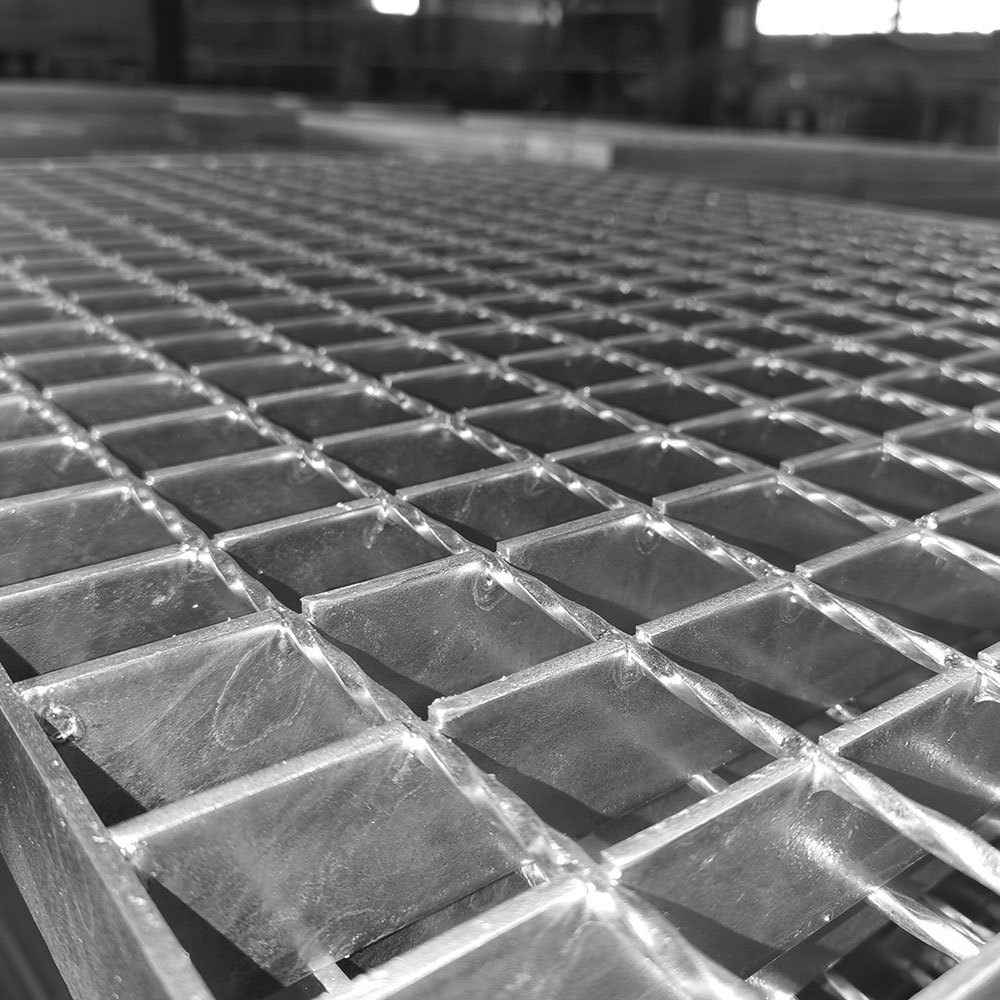

Steel springboards usually use high-quality carbon structural steel such as Q235 as raw materials, which have high strength and toughness and can meet the load-bearing requirements during construction. Its structural design is scientifically reasonable, generally a hollow plate-like structure, with anti slip treatment on the surface, such as pressing diamond or bar patterns, effectively enhancing friction and preventing construction personnel from slipping when walking on it. Some steel springboards will also be equipped with hooks or clamps at both ends to facilitate connection and fixation with scaffolding poles or crossbars, ensuring stability after installation.

Product Features

High strength and strong bearing capacity: Due to the use of high-quality steel, the steel springboard has excellent strength and rigidity, and can withstand the weight of construction personnel, tools, and building materials. Even under long-term use and frequent loads, it is not easy to deform, bend or break, providing a solid guarantee for construction safety.

Excellent anti slip performance: The anti slip pattern design on the surface greatly increases the friction between the sole and the springboard. It can effectively reduce the risk of slipping in damp, waterlogged environments, as well as in situations with sediment and oil stains, making it particularly suitable for use in complex environments such as outdoor construction.

Corrosion resistance and long service life: To improve the corrosion resistance of steel springboards, surface treatment such as hot-dip galvanizing is usually carried out. The galvanized layer can form a dense protective film on the surface of steel, isolating air, moisture, and other corrosive media, and delaying the corrosion rate of steel. A well treated steel springboard can have a service life of 5-8 years, far exceeding traditional wooden and bamboo springboards.

Moderate weight, easy to handle and install: Compared to bulky concrete springboards, steel springboards are lighter in weight, allowing construction personnel to easily handle and install them, greatly improving construction efficiency. At the same time, its standardized size design allows for quick assembly when setting up scaffolding, reducing installation time.

Recyclable and environmentally friendly economy: After reaching the end of its service life, steel can be recycled and reused without generating a large amount of waste like wooden and bamboo springboards, which meets environmental requirements. Moreover, although the initial procurement cost of steel springboards is relatively high, in terms of long-term use, they have a long service life, low maintenance costs, and better overall economic benefits.

Keywords:

Get A Quote

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.