Contact

700 meters south of Donglitun Village, Xiliangwa Township, Anping County, Hengshui City, Hebei Province

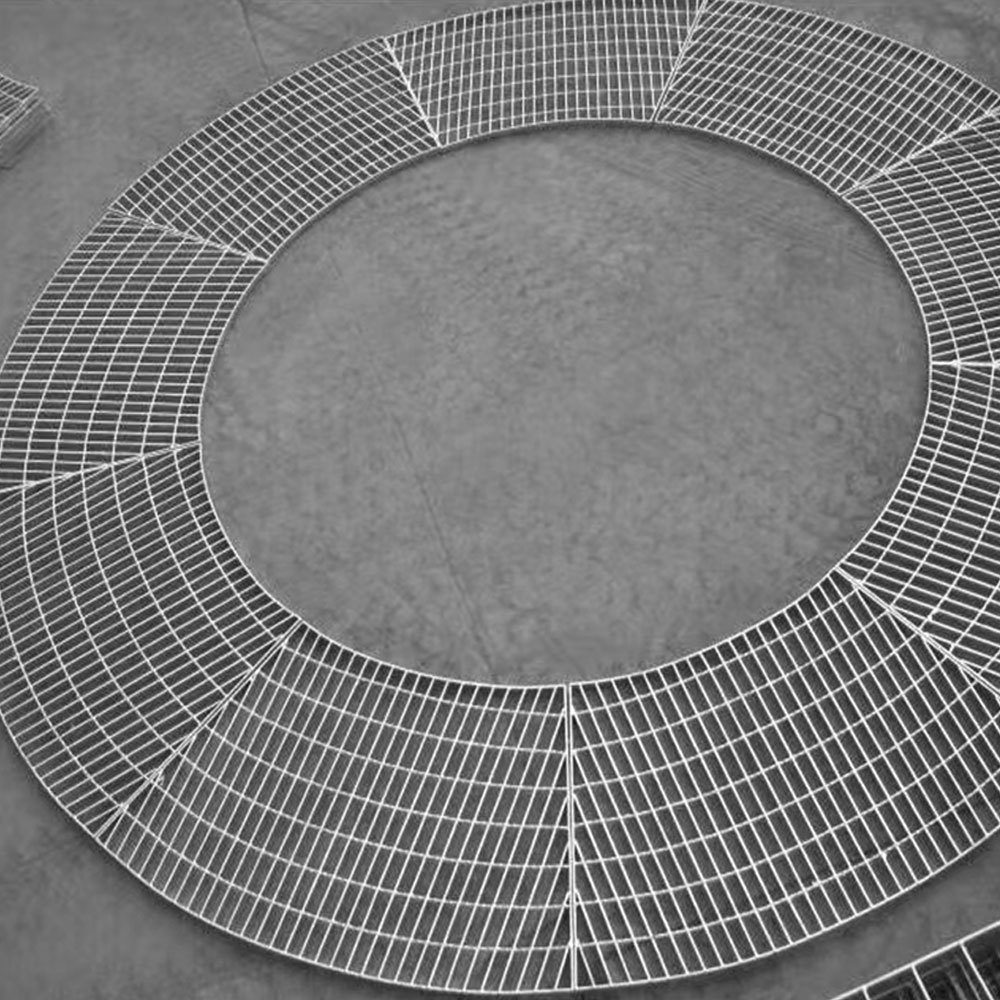

Steel Grating

- 产品描述

-

Product Introduction

Steel grating plate (also known as steel grating plate, grating plate) is an open grid shaped steel component composed of load-bearing flat steel and horizontal bars (usually twisted square steel, round steel or flat steel) orthogonally combined at a certain distance, fixed by welding or locking. It is widely used in many industrial, municipal, construction and other fields, mainly due to its significant advantages as follows:

1. Excellent ventilation, transparency, and drainage performance:

This is one of the core advantages of steel grating. Its open grid structure allows air to circulate freely, light to fully penetrate, and rainwater, sewage, oil, debris, etc. can smoothly fall through the grid.

Application manifestation: Especially suitable for environments such as chemical plants, sewage treatment plants, offshore platforms, car wash rooms, stair treads, platform walkways, ditch covers, etc. that require good ventilation, lighting, drainage, and prevention of water accumulation and corrosion.

2. Strong load-bearing capacity and lightweight structure:

Reasonably designed steel grating has a high strength to weight ratio. The load-bearing flat steel provides the main load-bearing capacity, while the crossbar plays a role in stabilizing the connection.

Advantage: Under the same load-bearing requirements, the self weight of steel grating is much lower than that of solid steel plates or concrete slabs. This not only reduces the load and cost of structural support, but also makes transportation and installation more convenient and efficient.

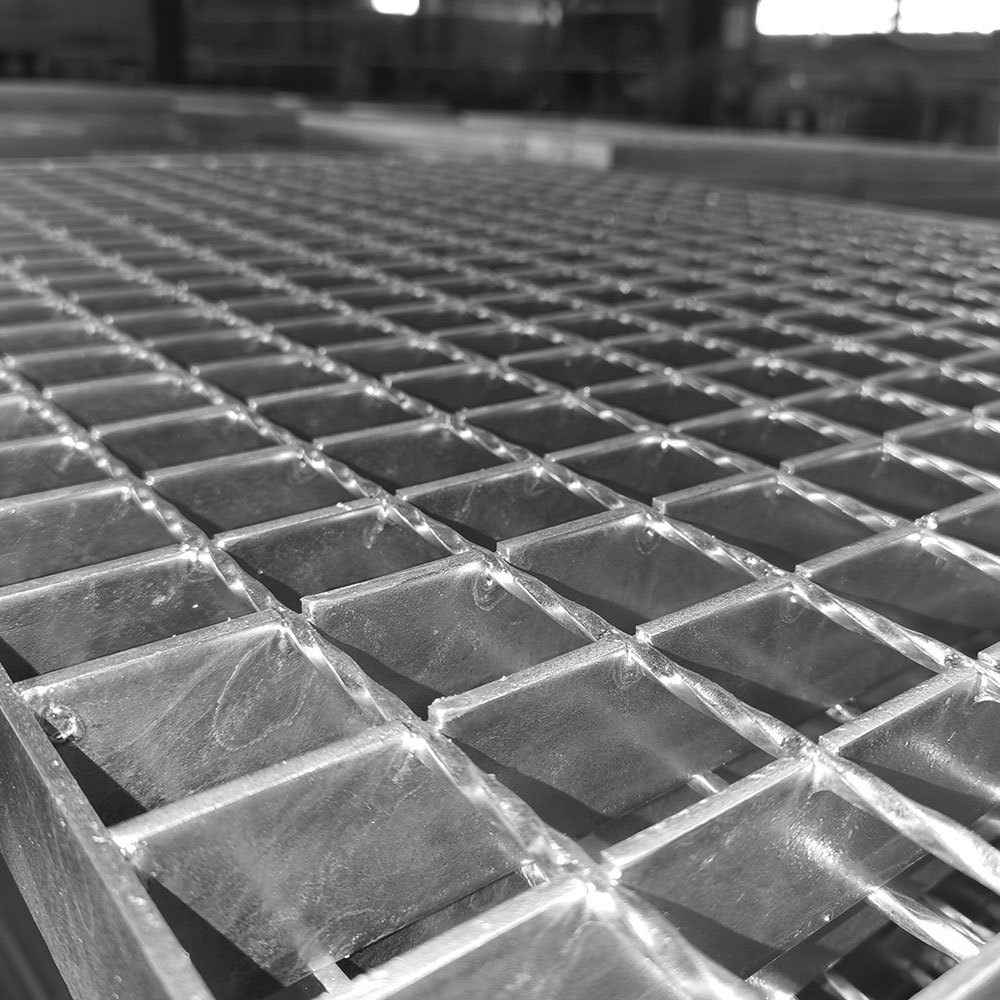

3. Good anti slip performance:

The surface carrying flat steel usually has a toothed (toothed steel grating), or its mesh structure itself can provide good friction.

Application manifestation: As a work platform, walkway, and stair step, it can provide reliable anti slip protection even in humid and oily environments, significantly improving work safety.

4. Corrosion resistance and long service life:

The most commonly used material for steel grating is carbon steel, which has undergone hot-dip galvanizing treatment. The galvanized layer provides excellent resistance to atmospheric and chemical corrosion.

Optional solution: For highly corrosive environments such as chemical and marine environments, stainless steel (304, 316, 2205, etc.), aluminum alloy, or fiberglass reinforced plastic (FRP) materials can also be used to meet higher anti-corrosion requirements.

Advantages: Durable and long-lasting, with extremely low maintenance costs (basically maintenance free), and low lifecycle costs.

5. Easy and fast installation:

Steel grating is usually produced in standard sizes or customized according to drawings, and can be installed directly upon arrival at the site.

Installation methods: commonly used welding (spot welding), installation clip fixation, angle steel inlay, etc. The installation process is simple and efficient, saving a lot of manpower and time costs.

6. Easy to maintain:

The surface is smooth, and the grid structure is not prone to accumulating dirt, dust, ice, and snow.

Maintenance: Daily cleaning is very convenient, usually only requiring high-pressure water flushing or simple cleaning. When inspecting the substructure or pipelines, only partial disassembly or no disassembly is required for observation, resulting in low maintenance costs.

7. Good economy (low overall cost):

Material cost: Although the initial procurement cost per unit area may be higher than some materials, its lightweight design brings significant economic advantages in terms of support structure savings, labor cost savings from quick installation, long lifespan, and extremely low maintenance costs (basically maintenance free) throughout the entire lifecycle of the project.

Reduce basic investment: Lightweight means lower requirements for foundations and supporting structures, further saving on civil engineering costs.

8. Beautiful and modern:

The neat grid lines and metallic texture (especially galvanized or stainless steel) give it a visual effect of modern industrial aesthetics.

Application manifestation: commonly used for exterior decoration of commercial buildings, skylights in shopping malls, municipal bridges, sidewalks, and other places that require both functionality and aesthetics.

9. Good fire resistance:

Steel itself is a non combustible material (Class A) that meets strict fire protection requirements.

In summary, the core advantage of steel grating lies in its unique grid structure, which perfectly integrates the characteristics of "openness" (ventilation, transparency, drainage) and "sturdiness" (load-bearing, durability), while also possessing the characteristics of safety (anti slip), economy (lightweight, low maintenance, long life), and convenience (easy installation, easy maintenance).

Additional explanation:

When selecting steel grating, it is necessary to choose the appropriate material (galvanized carbon steel, stainless steel, aluminum alloy, FRP), surface treatment method (hot-dip galvanizing, painting, untreated), grid size, and flat steel specifications based on the specific usage environment (load requirements, corrosiveness, whether anti slip is required, etc.). The relevant standards (such as YB/T 4001.1 in China, ANSI/NAAMM MBG 531 in the United States, and BS EN ISO 14122 in the United Kingdom) provide detailed design and selection guidance.

The emphasis of its advantages will vary in different application scenarios. For example, in chemical plants, corrosion resistance and drainage are more important; in platform walkways, load-bearing and slip resistance are more important; and in municipal engineering, aesthetics and durability may be more important.

Definition and Structure

Plug in steel grating is a grid shaped metal product made of flat steel (load-bearing flat steel) and twisted square steel (crossbar) as raw materials, through cross insertion, welding or locking processes. Its characteristic is that the horizontal bar intersects with the flat steel vertically, forming a regular grid structure, which has the advantages of high strength and strong impact resistance.

Core Features

-High strength and stability: The horizontal bar and flat steel are fixed by precision insertion and welding, with strong overall structural rigidity and better load-bearing capacity than ordinary steel grating, suitable for heavy-duty scenarios such as industrial platforms and docks.

-Anti slip and drainage: The surface friction of the grid structure is high, and the porosity is high (usually 30%~50%). It is not easy to accumulate water in rainy or humid environments, and its anti slip performance is outstanding.

-Easy installation: The size can be customized according to the needs, and it can be fixed by bolts or buckles during on-site splicing, reducing welding processes and improving construction efficiency.

-Corrosion resistance: The surface is usually hot-dip galvanized (zinc layer thickness ≥ 85 μ m), painted or treated with stainless steel, with strong corrosion resistance, suitable for outdoor or corrosive environments (such as chemical and marine engineering).

Classification and Process

1. Classified by plug-in process:

-Pressure welded plug-in steel grating: The flat steel and the horizontal bar are fixed by pressure resistance welding, and the welding points are firm, suitable for standard specification products.

-Press lock plug-in steel grating: The horizontal bar is embedded in the flat steel groove and locked by mechanical pressure, without the need for welding. It has a smoother appearance and is suitable for scenarios that require high surface aesthetics, such as shopping mall ceilings and municipal engineering.

2. Classified by material:

-Carbon steel (Q235, Q355): High cost-effectiveness, strong rust prevention ability after hot-dip galvanizing, and the most widely used;

-Stainless steel (304, 316): resistant to acid and alkali corrosion, suitable for food processing, coastal engineering, etc;

-Aluminum alloy: light weight (about 1/3 of carbon steel), anti-aging, suitable for aerial work platform.

Application scenarios

-Industrial field: factory equipment platforms, maintenance walkways, heavy machinery protective barriers;

-Municipal engineering: sewer ditch cover, sidewalk paving, parking lot drainage board;

-Architectural decoration: mall ceiling, stair treads, balcony guardrails;

-Energy industry: power plant platforms, oil drilling platforms, photovoltaic bracket bases;

-Transportation sector: dock loading and unloading platforms, high-speed rail platform anti-skid plates, bridge maintenance channels.

Key parameters for selection

-Flat steel specifications: commonly used width of 20-100mm, thickness of 3-10mm, determining bearing capacity;

-Horizontal bar spacing: commonly 30mm, 40mm, 60mm, the smaller the spacing, the better the anti slip performance;

-Surface treatment: hot-dip galvanizing (preferred for corrosion prevention), painting (color optional), polishing (stainless steel);

-Load requirements: The load-bearing capacity should be calculated based on the actual usage scenario (such as pedestrians ≤ 2.5kN/m ², vehicles ≥ 20kN/m ²)

Keywords:

Get A Quote

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.