Contact

700 meters south of Donglitun Village, Xiliangwa Township, Anping County, Hengshui City, Hebei Province

Scaffold Steel Pedals

- 产品描述

-

Product Introduction

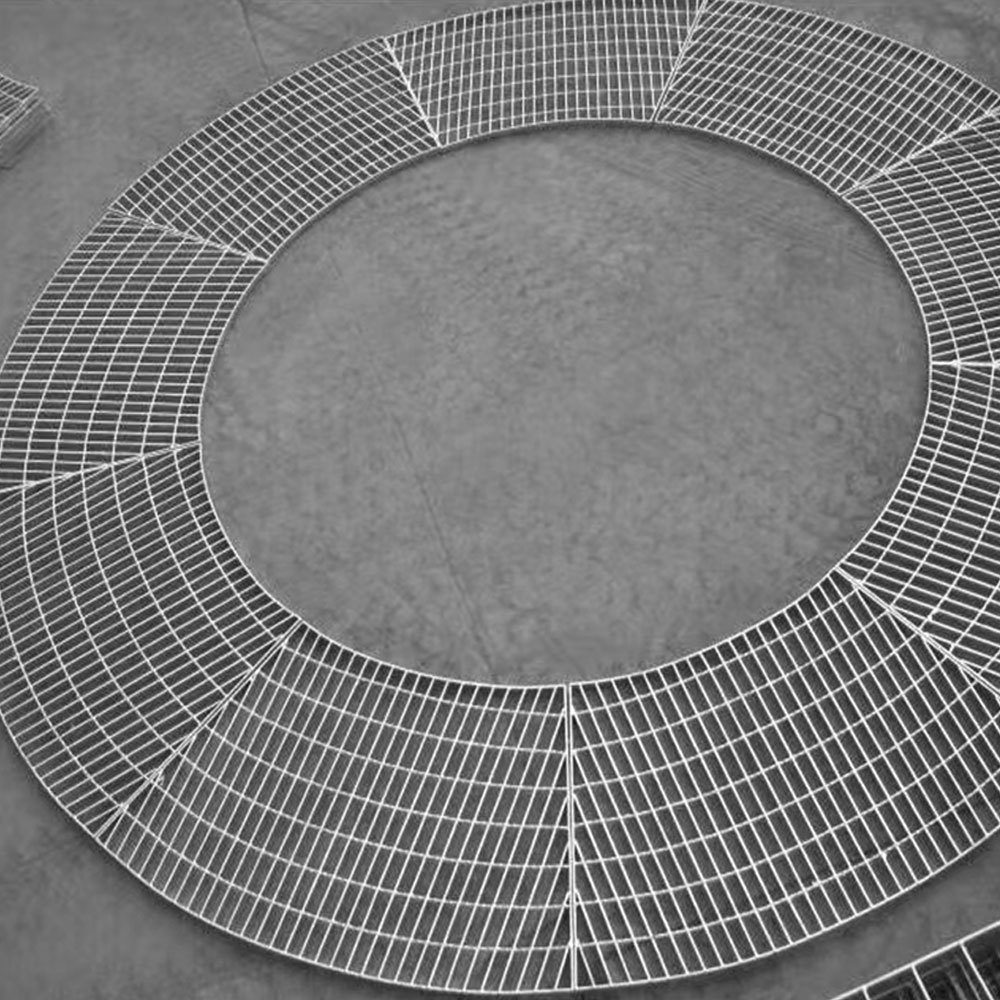

Scaffold steel pedals are one of the core components of scaffolding systems in construction, specifically designed to provide safe and stable walking and operating platforms for construction personnel during high-altitude operations. It plays an irreplaceable role in various construction projects, bridge construction, equipment installation and other scenarios with its sturdy structure and excellent performance, and is a key material to ensure construction safety and efficiency.

Product Structure and Materials

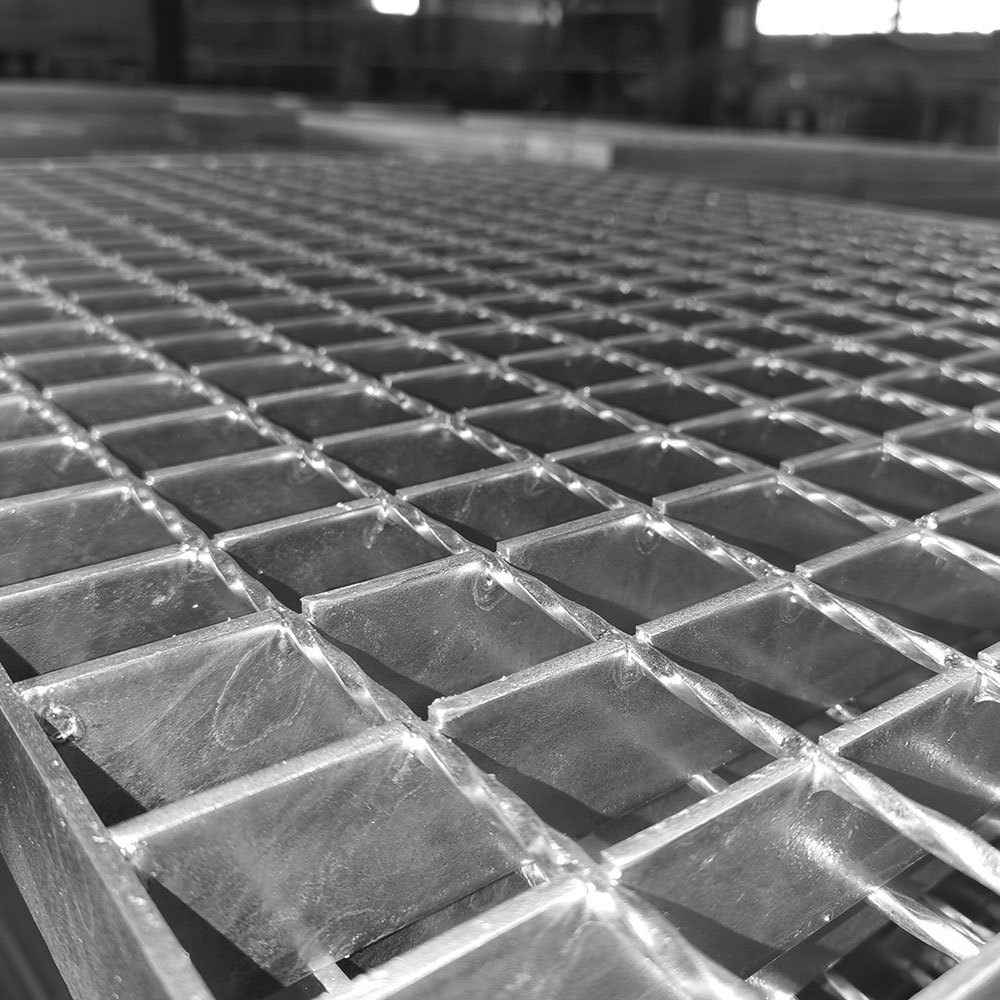

Scaffold steel pedals are usually made of high-quality Q235 carbon structural steel as raw material, which has high strength and good toughness, and can meet various load requirements during construction. Its structural design is simple and practical, generally in the form of a flat plate. The plate surface is processed by rolling to form evenly distributed anti slip patterns, such as diamond patterns, bar patterns, etc. The depth of the patterns is moderate, which can enhance friction without affecting the comfort of construction personnel walking. Some steel pedals will also be reinforced with ribs on both sides to improve the overall bending resistance and prevent deformation during long-term use.

Product Features

Strong bearing capacity: Due to the use of high-quality steel and reasonable structural design, the scaffold steel steps have excellent bearing performance. A single standard specification steel pedal can withstand a weight of several hundred kilograms and can accommodate multiple construction personnel and tools and materials simultaneously, ensuring the safety and stability of the construction process. For example, a steel pedal with a length of 2 meters can carry a weight of over 600 kilograms under uniform force.

Reliable anti slip performance: The anti slip pattern on the board is an important safety guarantee design. Whether in a dry environment or in damp, waterlogged, or oily conditions, it can effectively increase the friction between the foot and the pedal, greatly reducing the risk of slipping for construction personnel and providing solid safety protection for high-altitude operations. Easy installation and disassembly: The installation method of scaffold steel pedals is simple and efficient, usually connected and fixed to scaffold uprights and crossbars through hooks, buckles, or bolts. When installing, simply place the steel pedal in the designated position and secure it with the corresponding connectors, and a single person can complete the operation. It is also very convenient to disassemble, as it can be quickly removed from the scaffold for easy turnover, transportation, and storage.

Good corrosion resistance: In order to extend the service life, the surface of the scaffold steel pedal will undergo anti-corrosion treatment, commonly using hot-dip galvanizing process. The galvanized layer can form a dense protective film on the surface of steel, effectively isolating air, moisture, and other corrosive media, resisting erosion from various harsh environments, and enabling it to be used for a long time in outdoor, humid, and rainy environments, reducing maintenance costs.

Long service life: High quality steel materials, reasonable structural design, and comprehensive anti-corrosion treatment make the scaffold steel pedals have a long service life. Compared to traditional wooden pedals, its service life can be extended several times, and it can be reused multiple times, reducing the material cost of the project.

Keywords:

Get A Quote

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.